Flat Ribbon Cables: An ultimate guide on them

Are you considering incorporating flat ribbon cables into your assembly but are unsure whether that's a good idea? The article below will discuss the various applications of flat ribbon cables and their advantages.

What are Flat Ribbon Cables?

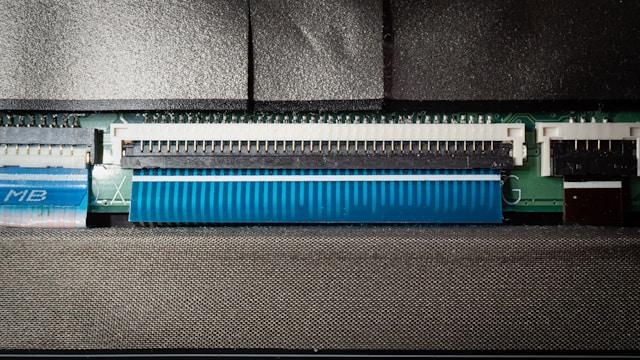

Flat ribbon cables are flat, rectangular cables made of parallel wires running parallel to each other. They are ideally made for mass-terminating IDC (insulation displacement contact) connectors.

Flat Ribbon Cable Applications

When ribbon cables were first launched, they were mainly used in the mainframe computer industry on tape machines, card readers, and card punching machines.

As flat ribbon cables became more popular, manufacturing materials and methods were brought forth to reduce costs and simplify assembly. Today, ribbon cables are widely used in printers, computers, and other electronic devices as interconnects for internal peripherals like floppy drives, hard drives, and CD drives.

Also, some older computer systems utilized ribbon cables for external connections. However, their ribbon shape interferes with the device cooling by disrupting airflow within the device case, which has resulted in the limited use of ribbon cables in computer designs in recent times.

Flat Ribbon Cable Advantages

Flexibility

Flat ribbon cables are flexible, which is helpful as they enable easy routing in confined spaces or applications with limited space for connecting two components. The ends readily conform to the mounting area and easily fasten to eliminate common causes of wiring malfunctions and errors.

Space Efficiency

There are generally two numbers specifying flat ribbon cables: the number of ways or conductors and the pitch or spacing of conductors. The most common spacing is 0.050 inches. However, according to application specifications, coarser and finer pitch cables are available from 0.156 inches to 0.025 inches with custom spacing. In various portable electronic devices, you can find cables with a pitch as low as 0.33 mm.

Due to the availability of standard conductors, the number of ways or conductors is normally restricted to certain values. These include 80, 64, 60, 50, 40, 37, 34, 36, 26, 25, 24, 20, 18, 16, 15, 14, 10, 9, 8, 6, and 4. The wires used in ribbon cables are normally standard copper wires ranging from size 34 AWG - 18 AWG or finer.

Flat ribbon cables are ideal for applications with limited or confined spaces, like electronics and computers.

Customizability:

You can get cables pre-formed to your precise specifications, as well as cables with black insulators, labels, and sticky tape.

Standard

You can identify a standard ribbon cable from its gray color. During the installation process, a red stripe on the edge of the cable serves as an identification stripe.

Edge Marked

Edge-marked cables usually have a striped mark on the 1st conductor that connects to pin one on the connector. The marking could be any color but is normally based on the center spacing or pitch of the cable. This identification method is ideal for cables with 2 or more IDC connectors, each connecting to an individual wire.

Color Coded

Commonly referred to as rainbow ribbon cable, color-coded cables use repeating color patterns to identify conductors. This pattern normally uses the industry standard color code, where red is for pins. and conductors 2, 12, 22, etc. On the other hand, brown is for pins and conductors 1, 11, 21, etc. Color-coded cables make identification and organization easier.

Single or Complex Multi-fold:

You can fold flat ribbon cables into custom configurations where spacing limitations are a design factor. Folding cables need special equipment and tooling to ensure the folds are permanent and complete. It saves costs since the cable arrives ready to use in the assembly.

Twisted Flat

Twisted ribbon cables have pairs of conductors bonded and twisted together. They feature alternating untwisted and twisted parallel sections. The design allows the termination of PCB headers and connectors with IDC ribbon cabling methods.

Round to Flat

The cable starts as a bundle of circular structures and unwinds for different applications. The design is perfect for restricted areas; however, the final segment still benefits from the advantages of the ribbon design.

Intermittent Bonding

This cable enables easy termination, organized wire placement, increased flexibility, and 1800 cable rotation at hidden sections. Also, it enables semi-automated and automated termination that saves time, improves efficiency, and reduces errors.

Bonded/ Hybrid

In several industries, like medical, commercial aviation, and industrial automation, one application often needs coaxial, power, and data cables but suffers complications due to environmental and space limitations. Hybrid cables combine wires of different types and sizes including shielded parallel pairs and coaxial, in one compact construction.

IDC Application

The IDC termination methodology enables the conductor of insulated cables and wires to make contact via a connection process that forces a sharp blade through the insulation. Therefore eliminating the need to strip the wire’s insulation before connecting.

Easy wiring

Ribbon cables are normally edge-marked or color-coded to minimize the risk of reversed connections and simplify installation by aligning cable conductors to specific pins on a connector.

Noise Reduction

Constant geometry and fixed conductor spacing enable consistent electrical characteristics like attenuation, capacitance, crosstalk, impedance, and time delay.

Custom Flat Ribbon Cable Assemblies at Cloom

Our team of skilled professionals at Cloom can help you design a custom ribbon cable tailored to the exact requirements of your project. Our team of professionals is trained in-house allowing us to offer a consultative approach for all our clients.

At Cloom, you can get various customizable options, such as;

* IDC, MDR, and other connector options

* Complete electrical continuity testing

* Pitch tolerance ± 0.05mm (0.002’’)

* FFC (flat flexible cable) alternatives

* 2 - 100 conductors in high-density to wide-spacing configurations

* Temperature range of —550C - +2000C

* Integration with electronic materials and components

Conclusion

For all your needs, contact Cloom, the leading custom wiring harness and cable assembly manufacturer.