DXF Files for Metal Plasma Cutting

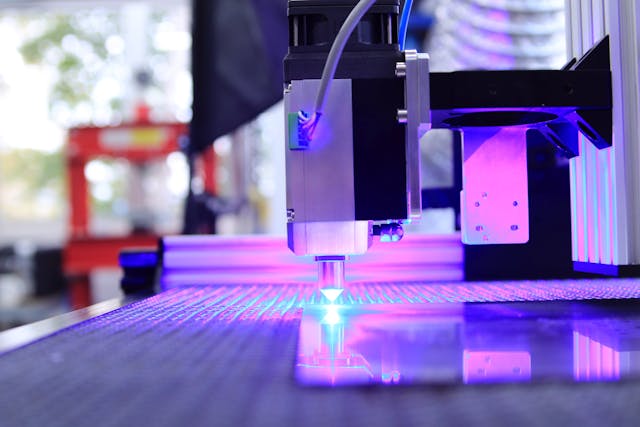

Plasma cutting is an incredibly efficient technique for precisely shaping metal, making it a staple in industries ranging from automotive manufacturing to artistic fabrication. The process uses a plasma torch to cut through conductive metals such as steel, aluminum and copper with remarkable accuracy. A key component of modern plasma cutting is the DXF (Drawing Exchange Format) file, which serves as a detailed digital guide for the cutting equipment. In this article, we will look at how DXF files are used in metal plasma cutting, why they are so effective, and the key factors to consider when using DXF files for metal.

What are DXF files?

DXF files are vector-based 2D drawings that serve as a universal format for exchanging design data. Developed by Autodesk, this format is compatible with various computer-aided design (CAD) and computer-aided manufacturing (CAM) software. Unlike raster images, which are made up of pixels, DXF files describe geometric shapes using mathematical equations, ensuring precision and scalability.

In the context of plasma cutting, DXF files translate designs into machine-readable instructions. They define the paths the plasma cutter will follow, specifying where to start, stop, and move to achieve the desired cuts.

Preparing DXF Files for Plasma Cutting

The process of preparing a DXF file for plasma cutting involves several critical steps. Proper preparation ensures that the cutting machine interprets the design accurately and produces clean, precise cuts.

1. Design Creation

The first step is to create the design in CAD software such as AutoCAD, SolidWorks, or CorelDRAW. Here are some considerations during the design phase:

- Simplify the geometry: Plasma cutting works best with clean, continuous lines. Overly complex or intricate designs can lead to errors or require additional processing time.

- Define cut paths: Distinguish clearly between areas to be cut and material to be left intact. Use layers or color codes as necessary.

- Scale and Dimensions: Make sure the design is scaled to the exact dimensions of the workpiece. Incorrect scaling can waste material and result in incorrect parts.

2. Optimization for Plasma Cutting

Plasma cutting presents unique challenges such as kerf (the width of the cut) and heat distortion. It is important to adjust the DXF file for these factors:

- Allow for kerf width: The cutting tool removes a small amount of material as it passes through. To maintain accurate dimensions, offset the cutting paths by the kerf width of the tool.

- Minimize heat buildup: Avoid densely packed cuts or prolonged exposure in one area, as excessive heat can distort the metal. Strategic placement of cutting paths can mitigate this problem.

3. File Export and Compatibility

Once the design is complete, export it in DXF format. Ensure compatibility with the specific plasma cutting software or CNC (computer numerical control) system. Verify that the file contains only the necessary layers and that redundant elements, such as overlapping lines or unconnected nodes, have been removed.

Using DXF files with plasma cutting machines

When the DXF file is ready, it is transferred to the control system of the plasma cutting machine. The steps to perform the cutting process include loading the file, generating the tool path, and operating the machine.

1. Loading the file

Load the DXF file into the plasma cutter software. Common tools include

- CAM software: Converts DXF files to G-code, the language CNC machines understand.

- Preview tools: Allow operators to simulate the cutting process, ensuring that the file matches the material size and orientation.

2. Generating Toolpaths

The software generates toolpaths based on the design. At this stage, operators can

- Optimize the cutting sequence to reduce travel time.

- Add lead-ins and lead-outs to ensure smooth entry and exit points for the plasma arc.

- Check for possible collisions or problematic cuts.

3. Executing the Cut

With the toolpaths in place, the plasma cutter executes the cuts according to the instructions in the DXF file. During this phase, machine operators monitor the process and adjust parameters such as cutting speed, torch height, and gas flow to maintain quality.

Key considerations when using DXF files for plasma cutting

While DXF files provide a robust framework for metal plasma cutting, achieving consistent results requires attention to several key factors:

1. File Quality and Accuracy

Ensure that the DXF file is free of errors. Common problems include

- Overlapping lines: Multiple lines in the same location can confuse the software and result in duplicate cuts.

- Disconnected paths: Open shapes or disconnected nodes can interfere with the cutting process.

- Unnecessary elements: Remove text annotations, hidden layers, or unnecessary details that may interfere with the edit.

2. Material Selection and Thickness

Different metals and thicknesses require specific machine settings. Make sure the DXF design is appropriate for the material:

- Thin materials may require higher speeds and lower amperage to avoid distortion.

- Thick metals require slower RPMs and higher amperage to achieve full penetration.

3. Machine Calibration

Proper machine setup is critical to translating DXF designs into accurate cuts. Key considerations include

- Torch Height: The distance between the plasma torch and the metal surface affects cut quality. Automatic torch height control systems can help maintain consistency.

- Cutting Speed: Excessive speed can leave incomplete cuts, while slow speeds can produce rough edges.

- Air Pressure and Gas Mixture: These affect the stability of the plasma arc and cutting efficiency.

4. Post-processing requirements

After plasma cutting, parts may require post-processing such as deburring or grinding to remove slag or refine edges. The DXF design should account for post-processing by avoiding overly fine details that are difficult to clean.

Benefits of DXF files for plasma cutting

There are many advantages to using DXF files for plasma cutting:

- Precision: Vector-based designs ensure sharp, precise cuts.

- Versatility: DXF files are compatible with a wide range of software and machines, making them ideal for collaborative workflows.

- Scalability: Designs can be easily resized without losing detail to accommodate projects of varying sizes.

- Efficiency: Automating the cutting process reduces manual labor, material waste, and production time.

Challenges and how to overcome them

Despite their benefits, DXF files can present challenges in plasma cutting. Here's how to overcome common problems:

- File complexity: Overly detailed designs can slow down software or cause bugs. Simplify unnecessary detail without compromising design intent.

- Software Compatibility: Not all DXF files are formatted the same. Test files in the intended CAM software to confirm compatibility.

- Material Limitations: The cutting process may struggle with certain materials, such as reflective surfaces like polished aluminum. Adjust machine settings to overcome these challenges.

Conclusion

DXF files have revolutionized metal plasma cutting by providing a reliable, accurate way to translate digital designs into physical parts. By carefully preparing DXF files, optimizing them for plasma cutting, and taking into account machine and material considerations, users can achieve outstanding results. As technology advances, the integration of DXF files with plasma cutting systems will continue to increase productivity and creativity across multiple industries.

Whether you're producing industrial components or artistic metalwork, understanding how to work with DXF files will ensure that your plasma cutting projects are both efficient and successful.