Strengthening Industrial Security with Advanced 3D Printing Technologies

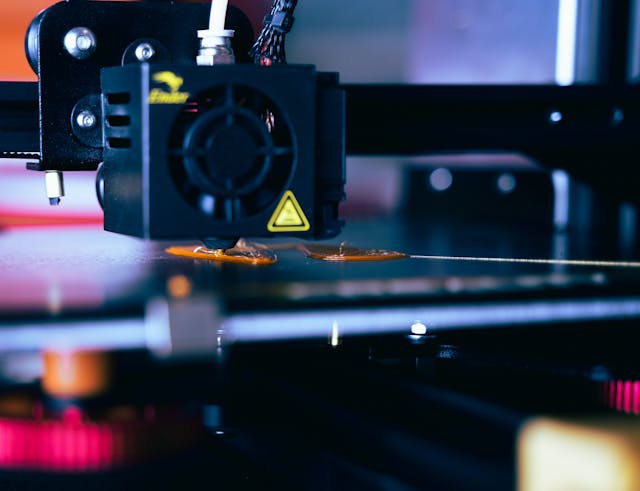

3D printing has become an essential tool in modern manufacturing, providing businesses with new ways to produce secure, high-quality components while reducing reliance on complex supply chains. However, as additive manufacturing gains widespread adoption, security concerns related to intellectual property, supply chain integrity, and cyber threats are becoming more significant.

From preventing counterfeit production to ensuring the protection of digital design files, security-focused applications of 3D printing are shaping the future of defense, aerospace, healthcare, and industrial manufacturing. Technologies such as Selective Laser Sintering (SLS) play a crucial role in creating strong, tamper-resistant parts for security-sensitive industries.

As the manufacturing world continues to shift toward digital and decentralized production, addressing security risks in 3D printing will be essential for businesses that rely on precision, confidentiality, and supply chain resilience.

How Intellectual Property Risks Are Changing with 3D Printing

The ability to digitally store, modify, and transmit 3D design files has created new vulnerabilities in product development. Unlike traditional manufacturing, where proprietary designs remain in controlled environments, additive manufacturing relies on digital blueprints that can be stolen, duplicated, or modified without authorization.

Industries such as automotive, aerospace, and consumer electronics face increasing risks of intellectual property theft as 3D printing expands. Companies are adopting new security protocols to protect digital designs, including:

- Digital watermarking – Embedding invisible markers within CAD files to track authenticity and detect unauthorized copies.

- Blockchain-based verification – Using decentralized ledgers to validate the origin and ownership of 3D designs.

- AI-driven design protection – Implementing machine learning algorithms that recognize alterations in original design files.

Securing digital assets is just as important as protecting physical prototypes and end-use products. Businesses that prioritize secure 3D printing workflows are better equipped to prevent the unauthorized replication of proprietary technology.

The Role of 3D Printing in Counterfeit Prevention and Supply Chain Security

Supply chain security remains one of the biggest concerns in manufacturing. Traditional production processes involve multiple suppliers, distributors, and assembly points, creating opportunities for counterfeit products to enter circulation.

3D printing allows manufacturers to reduce supply chain complexity by enabling on-demand production and localized manufacturing, ensuring that critical components remain under controlled conditions. This shift enhances security by:

- Minimizing overproduction, which reduces the number of parts in circulation that could be counterfeited.

- Allowing direct production at secure locations, limiting the need for third-party suppliers.

- Embedding authentication features such as micro-text, QR codes, or structural watermarks that verify genuine parts.

Industries such as medical devices, aerospace, and defense have adopted 3D printing to ensure that essential components meet strict security requirements.

For manufacturers looking to improve supply chain security and precision production, more details are available through 3D printing Boston services at https://www.upsideparts.com/3d-printing.

SLS 3D Printing in Security-Sensitive Applications

Selective Laser Sintering is one of the most trusted 3D printing technologies for applications where strength, precision, and security are required. Unlike other additive manufacturing methods, SLS does not require support structures, making it ideal for complex and high-performance components.

Industries relying on secure, high-performance 3D printing include:

- Aerospace and Defense – Production of lightweight, impact-resistant parts that meet strict regulatory standards.

- Medical and Biotech – Secure manufacturing of custom prosthetics, dental aligners, and surgical instruments with precise patient-specific customization.

- Automotive and Heavy Machinery – Creation of custom mechanical components that require strong, wear-resistant properties.

Because SLS offers excellent material properties and reliability, it is increasingly used in classified manufacturing environments that require tamper-proof, regulation-compliant production.

More details on advanced SLS 3D printing solutions can be found at https://www.upsideparts.com/3d-printing/sls.

Physical Security in 3D Printing during Post-Processing and Support Removal

While digital security is critical in additive manufacturing, physical security and safe handling of printed components also play a key role. Many 3D-printed parts require post-processing steps, including support removal and surface finishing, which can introduce risks if not handled correctly.

Incorrect support removal can result in part damage, safety hazards, and reduced structural integrity. Using the right techniques ensures that printed components maintain their strength and precision while minimizing risks associated with manual handling.

Best practices for secure support removal include:

- Using precision tools such as pliers and cutters designed for specific support materials.

- Applying controlled heat or chemical methods to remove supports without warping the part.

- Following step-by-step post-processing workflows to ensure consistency and reduce material loss.

Industries that rely on precision manufacturing use structured post-processing protocols to maintain part reliability. Those looking for guidance on secure support removal methods can refer to detailed instructions at https://www.upsideparts.com/post/how-to-remove-supports-from-3d-prints.

How Secure 3D Printing is Changing Manufacturing

The increasing adoption of additive manufacturing in high-security industries is driving new advancements in material science, encrypted design protection, and AI-powered monitoring systems.

Manufacturers are integrating tamper-resistant printing techniques, blockchain-based design verification, and advanced threat detection tools to ensure secure, high-precision production.

As 3D printing continues to evolve, companies that embrace security-focused additive manufacturing strategies will gain a competitive advantage in industries where precision, compliance, and confidentiality are essential.